Rubber Process & Rheological Properties Tester >

Strength Tester >

Viscoelasticity Tester >

Fatigue Tester >

Friction Tester >

Environmental Testing Machines >

Hardness Tester & Thickness Gauge >

-

Rubber Material Hardness Tester & Thickness Gauge >

- IRHD syspem

- Special durometers

- Thickness gauge

- Hildebrand automatrcially operating stand

- Hildebrand durometer operating stand

- Digital durometer&Hilmeasure software

- Sample holder

- Rubber test blocks(RTB)for micro IRHD

- Thickness Gauge

- Base Of Hardness Tester

- Shore A Hardness Tester

- Rockwell Hardness Tester

- Rockwell Hardness Tester

- Micro IRHD Hardness Tester

- Macro IRHD Hardness Tester

-

Leather Softness & Hardness Tester >

Weight & Density Testing Machines >

Physical & Chemical Analyzer >

Appearance Quality Testing Machines >

Sample Machines >

Environment Quality Testing >

Plastometer Standard Rubber >

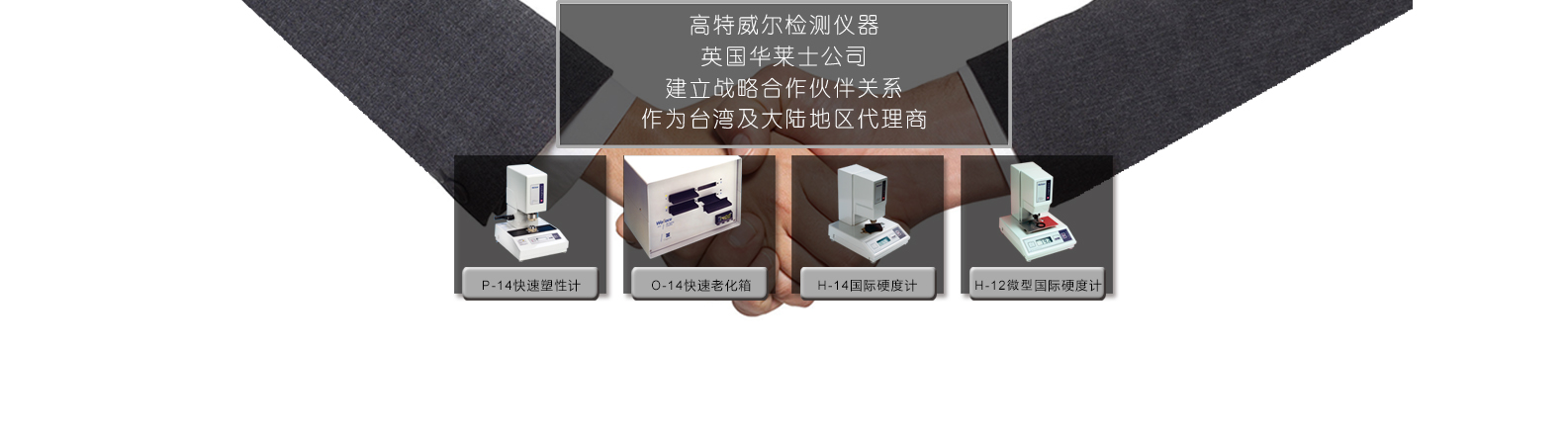

Name

Micro IRHD Hardness Tester

Model

H-12

The Wallace H-12 is a digital bench-mounted hardness tester that measures in IRHD the hardness of most rubber samples. In particular it has been designed to accurately test thin sections and small test pieces such as O-rings.The robust, ‘C’ frame design allows the operator easy access from front and sides to safely load and remove samples. The indenter mounting is frictionless and its position sensed by an LVDT, providing the instrument with outstanding sensitivity. Adjustable anti-vibration feet reduce the effect of external vibration.

BS 903: Pt. A26, DIN 53519, ISO 48, ASTM D 1415

uThe robust, ‘C’ frame design allows the operator easy access from front and sides to safely load and remove samples. The indenter mounting is frictionless and its position sensed by an LVDT, providing the instrument with outstanding sensitivity. Adjustable anti-vibration feet reduce the effect of external vibration.

uBy simply pressing the start button, the instrument functions automatically, allowing accurate, repeatable results to be recorded in much less time than traditional models. As minimal training is required, new operators soon become confident with the H12, achieving consistent readings from the outset.

uA range of optional sample tables is available, designed to locate samples of varying shapes and special sample holding fixtures. It includes the O-ring adaptor (H19/ORA) that ensures the centre of the ring is directly beneath the centre line of the indenter.

uRubber Hardness Test Blocks:The test blocks are for use as a check to ensure instruments are functioning properly and read correctly. They are not intended as standards with specific hardness values. Test blocks should be returned to Wallace every 12 months for re-calibration.

Accuracy: <0.1

Indenter shape: sphere

Indenter diameter: 0.395mm

Load: quiescent load

Indenter load: 235mN

Preload: 8.3mN

Second load: 145mN

Load time: 5+30sec

Specimen thickness: min.1.5mm

Dimension (W×D×H): 214mm×255mm×300mm

Weight: 7.5kg