Rubber Process & Rheological Properties Tester >

-

Plastimeter >

-

Mooney Viscometer >

-

Moving Die Rheometer >

-

Foam Force Rheometer >

-

Rubber Process Analyzer >

-

Polymers’ Fluidity & Viscosity Test >

-

Polymers PVT Tester >

-

Melt Flow Indexer >

-

Carbon Black Dispersion Tester >

Strength Tester >

-

Universal Testing Machines >

- Servo Control High/Low Temperature Universal Testing Machine

- Servo Control System Concrete Compression Tester

- Open Crosshead Servo Control Universal Testing Machine

- Servo Control Universal Testing Machine

- Servo Oil Hydraulic System Horizontal Type Testing Machine

- Servo Control System Desktop Tensile Strength Tester

- Servo Control System Universal Testing Machine

-

Tire Testing Machine >

-

Impact Tester >

-

Tape Adhesion & Retentivity Tester >

-

Bursting Strength Tester >

-

Footwear Mechanical Properties Tester >

-

Footwear Impact Tester >

Viscoelasticity Tester >

-

Dynamic Mechanical Analyzer >

-

Frequency & Temperature Scan >

-

Elasticity Tester >

-

Creep Stress Relaxation Tester >

Fatigue Tester >

-

Dynamic Fatigue Tester >

-

Flexometer >

-

Tensile Fatigue Tester >

-

Flex-Cracking Fatigue Tester >

-

Belt Fatigue Tester >

-

Hose Fatigue Tester >

-

Footwear Fatigue Tester >

- Upper Material Flexing Tester

- Shoe Steel Shank Fatigue-Resistance Tester

- Upper Material Flexing Tester

- Upper Material Flexing Tester

- Bally Leathers Flexing Tester

- Slide Fasteners Reciprocating Tester

- Shoe Bending Waterproofness Tester

- Shoe Bending Waterproofness Tester

- Shoe Flexing Tester

- Inserts Flexing Resistance Tester

- Outsole Flexing Tester

- Outsole Belt Flexing Tester

- Fiberboard Flexing Tester

- Ross Flexing Tester

- Shoe Bending Tester

- Shoe Flexing Tester

- Shoe Flexing Tester

Friction Tester >

-

Abrasion Resistance Tester >

-

Coefficient Of Friction Tester >

-

Footwear Friction & Abrasion Resistance Tester >

Environmental Testing Machines >

-

Heat Aging Resistance Tester >

-

Low Temperature Resistance Tester >

-

Temperature & Humidity Tester >

-

Thermal Shock Tester >

-

Ozone Tester >

-

Accelerated Weathering Tester >

-

Discoloration Meter >

-

Salt Spray Tester >

-

HDT/VICAT Tester >

-

Medium Resistance Tester >

-

Footwear Waterproofness Tester >

-

Footwear Heat Resistance Tester >

-

Electric Shock Resistance Tester >

Hardness Tester & Thickness Gauge >

-

Rubber Material Hardness Tester & Thickness Gauge >

- IRHD syspem

- Special durometers

- Thickness gauge

- Hildebrand automatrcially operating stand

- Hildebrand durometer operating stand

- Digital durometer&Hilmeasure software

- Sample holder

- Rubber test blocks(RTB)for micro IRHD

- Thickness Gauge

- Base Of Hardness Tester

- Shore A Hardness Tester

- Rockwell Hardness Tester

- Rockwell Hardness Tester

- Micro IRHD Hardness Tester

- Macro IRHD Hardness Tester

-

Leather Softness & Hardness Tester >

Weight & Density Testing Machines >

-

Moisture Determination Balance >

-

Rubber Hydrometer >

-

Footwear Density Testing Machines >

Physical & Chemical Analyzer >

-

Heat Analyzer >

-

Ultimate Analyzer >

-

PH Meter >

-

Melting Point Apparatus >

-

Melting Point Apparatus >

-

Ash Testing Machines >

-

Carbon Black Tester >

-

Surface Area Analyzers >

-

Hazemeter >

-

Torque Rheometer >

Appearance Quality Testing Machines >

-

Light Source >

-

Crock Meter >

-

Color Atlas & Color Scale >

Sample Machines >

-

Small Production Machines >

-

Sample Machines >

- Sample Cutter

- Hydraulic Cutter

- Rubber Slicing Machine

- Manual Cutter

- Sample Cutter

- Full Automatic V-Notch Sampling Machine

- V-Notch Sampling Machine (For Impact Specimen)

- V-Notch Sampling Machine (For Impact Specimen)

- Hard Plastic Specimen Cutting Machine

- Double wheel sampling buffing machine

- Lamination of PVC Plastic Press Tester

- Auto-Pneumatic Cutter Press

- Cutter Press

- Lamination of PVC Plastic Press Tester

Environment Quality Testing >

-

Gas Analyzer >

-

Particle Sense >

-

Soil Property Sensors >

-

Water Quality Probe >

Plastometer Standard Rubber >

-

Plastometer Standard Rubber >

Name

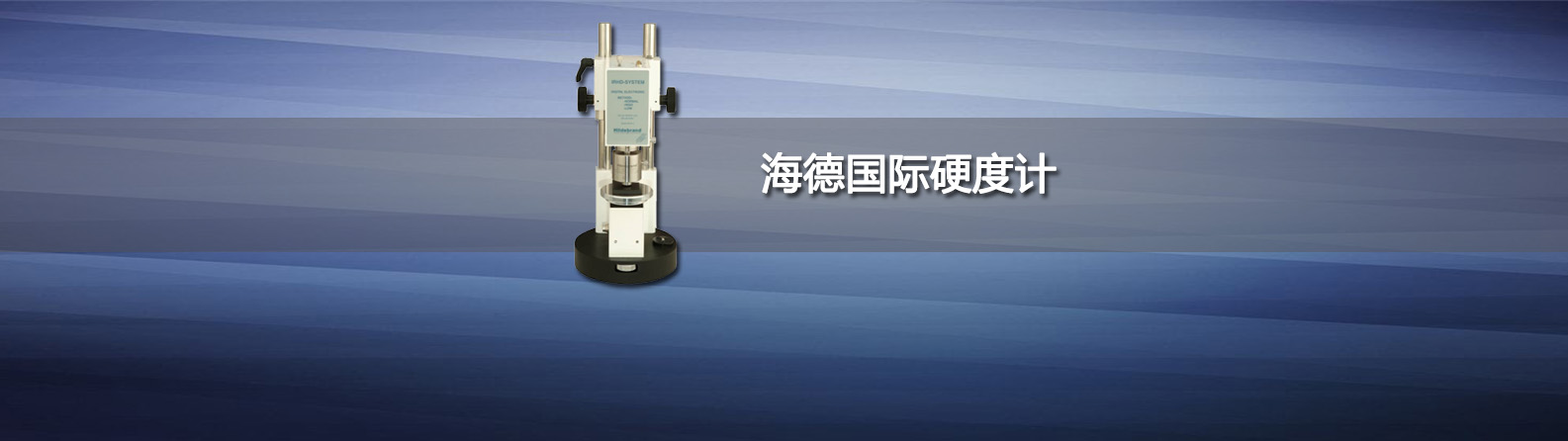

Hildebrand durometer operating stand

Model

OS-2

HILDEBRAND DUROMETER OPERATING STAND

English The Hildebrand Durometer Operating Stand Model OS-2 allows for accurate and repeatable Durometer readings. It rules out subjective test errors, which may be caused by differing load application forces or non-vertical application of the durometer to the test piece. Features: The Durometer Operating Stand works on the constant load principle. The sample is positioned on the support table. The durometer is lowered shock-free by means of a manually operated lever. The hardness value can be read directly from the Durometer. The stable Durometer-unit consists of Aluminium. Due to the low weight the durometer-unit can be easily adjusted in height. Small and big samples can be tested in the Durometer Operating Stand. A crash ring - mounted on the column - eliminates a crash between durometer and support table, when lifting or lowering the Durometer-unit.

English The Hildebrand Durometer Operating Stand Model OS-2 allows for accurate and repeatable Durometer readings. It rules out subjective test errors, which may be caused by differing load application forces or non-vertical application of the durometer to the test piece. Features: The Durometer Operating Stand works on the constant load principle. The sample is positioned on the support table. The durometer is lowered shock-free by means of a manually operated lever. The hardness value can be read directly from the Durometer. The stable Durometer-unit consists of Aluminium. Due to the low weight the durometer-unit can be easily adjusted in height. Small and big samples can be tested in the Durometer Operating Stand. A crash ring - mounted on the column - eliminates a crash between durometer and support table, when lifting or lowering the Durometer-unit.