Rubber Process & Rheological Properties Tester >

-

Plastimeter >

-

Mooney Viscometer >

-

Moving Die Rheometer >

-

Foam Force Rheometer >

-

Rubber Process Analyzer >

-

Polymers’ Fluidity & Viscosity Test >

-

Polymers PVT Tester >

-

Melt Flow Indexer >

-

Carbon Black Dispersion Tester >

Strength Tester >

Viscoelasticity Tester >

Fatigue Tester >

Friction Tester >

Environmental Testing Machines >

Hardness Tester & Thickness Gauge >

Weight & Density Testing Machines >

Physical & Chemical Analyzer >

Appearance Quality Testing Machines >

Sample Machines >

Environment Quality Testing >

Plastometer Standard Rubber >

Name

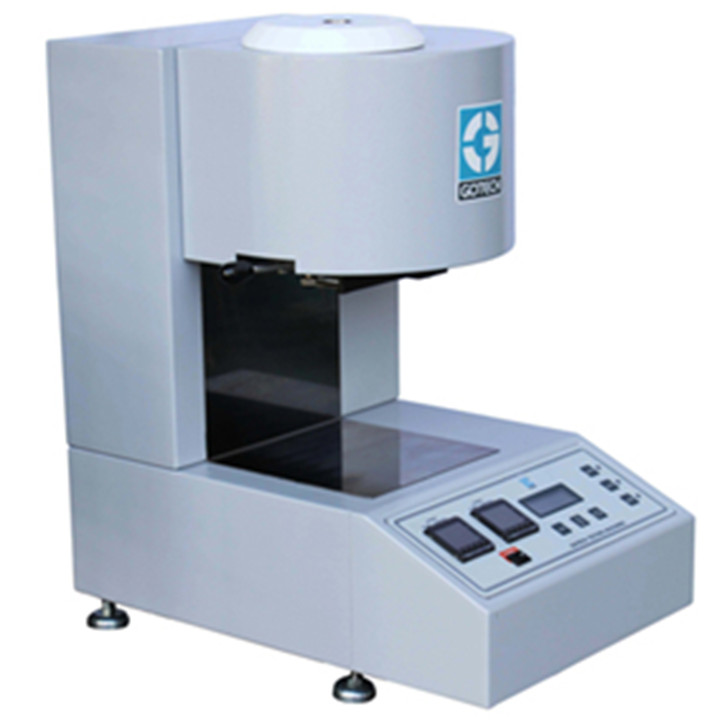

Melt Flow Indexer

Model

GT-7100-MI

Description

This tester is used to measure the rate of extrusion of molten resins through a die of specified length and diameter under prescribed conditions of temperature, load and piston position in the cylinder for measuring the flow rates of polymer in producing process.

With the PID temperature control in two zones of the die cavity, this machine can uniformly heat the plastic sample in the die cavity. The use of the high- quality thermal insulation material can reduce the error caused by heat loss in the process of testing.

Standard

ASTM-D1238、ASTM-D3364、GB/T 3682、ISO-1133、JIS-K7210

Key Technical Data

◆ Temperature control:Room temp. ~450 °C(accuracy ± 0.1°C),PID control, include overheat protection.

◆ Temp display: Imported digital type temperature controller

◆ Load: 1000g, 1200g, 2160g, 3800g, 5000g, 7160g, 10000g, 12500g, 21600g,(Optional combination of weights)

◆ Flow rate of applicable materials: 0.15~50g / 10 min

◆ Auto cutoff device: Auto / manual selection , time interval 99min59sec

◆ Loading Method: Manually pressurize

◆ Accessories:

——Piston rod

——Reamer

——Cylinder cleaning rod

——Cylinder brush

——Leveling rod

——Die gauge set (go/no go)

——Die cleaning drill

——Filling funnel

——Observation mirror

◆ Dimension (W×D×H):40 × 51 × 60 cm

◆ Weight:42 kg (without weights)

◆ Power: 1∮,AC220V,50/60Hz,5A (Specified by user)